Plastic Injection Molds

Plastic injection molding is the process used to produce low or high volumes of custom plastic parts for commercial and industrial use. From intricate automobile safety components to simple products like business card holders, the applications span a range of industries.

Prototype Injection Molding

A custom plastic part may go through several stages as it evolves from an idea to reality. A 2D drawing of the part provides a base for creating a detailed 3D rendering of the part design. After a custom plastic part has been clearly illustrated and may seem ready for production, there may be some very good reasons to consider prototype injection molding (making injection molded prototypes) before going into mass production.

Custom Injection Molding

TISS includes production capabilities for many different industries, plastic materials, and specialty add-ons for your custom plastic parts. Our focus is on production runs of 100 to 100,000 units per order. We know every custom injection molding project is different, but every TISS Mold customer enjoys our key values: High quality custom plastic injection molds and custom parts with reliable on-time deliveries Outstanding attention to customer needs through advanced quality planning Fast quotes and delay free communication Friendly and knowledgeable customer service

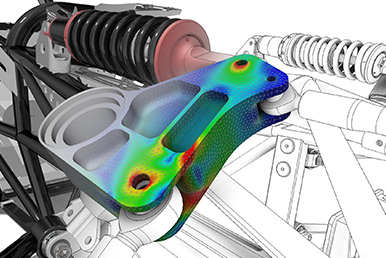

Design & Engineering

At TISS Mold, we know that not every customer has CAD software or the experience to design 3D parts from scratch. We also understand that our customers may need quality advice on the design of their plastic parts if they are unfamiliar with the process. All of our CAD design support services are free to our customers when they purchase their custom parts from us. We have capabilities to make 3D files from even the simplest of 2D drawings. Just send us your drawings and we’ll create your functional 3D models.Design and Engineering

Assembly & Extras

Enjoy Our Add On Options Commonly requested manufacturing add on items can increase the cost of injection molded parts, but we enjoy being a full service injection molding company for our clients. Some complex or critical appearance parts may require one or more of the following items after they are injection molded: